– The perfect combination of injection molding and thermoforming enables manufacturing of thermoplastic composites that is ready for large series production

– The perfect combination of injection molding and thermoforming enables manufacturing of thermoplastic composites that is ready for large series productionFit for large series

“In Mexico we are finding an increasing demand for cost-effective lightweight construction solutions, especially for the automotive and transport sector,” says Emilio Lopez, Manager of the subsidiary of the KraussMaffei Group in Mexico. “At the Plastimagen show, therefore, we will not only exhibit our extensive expertise with injection molding. We will also demonstrate the FiberForm process, a method of manufacturing components made of thermoplastic composites in a way that is ready for large series production.” A CX 300 – 1400 will produce airbag housings made of fiberglass-reinforced polyamide with a shot weight of 350 g in cycle times of 45 seconds. “With this,” Lopez continues, “we precisely meet the requirements of the automakers (OEMs) and the Tier 1 suppliers in the Mexican market.” Another advantage is the weight reduction and fast further processing: The airbag housing manufactured at the Plastimagen for Japanese automotive supplier Takata Corporation is approximately 40 percent lighter than conventional components made of metal, does not have to be reworked and is ready to install immediately. Partner companies at the trade fair exhibit are Christian Karl Siebenwurst, Lanxess, Bond Laminates, Koch Maschinen Technik and GWK.

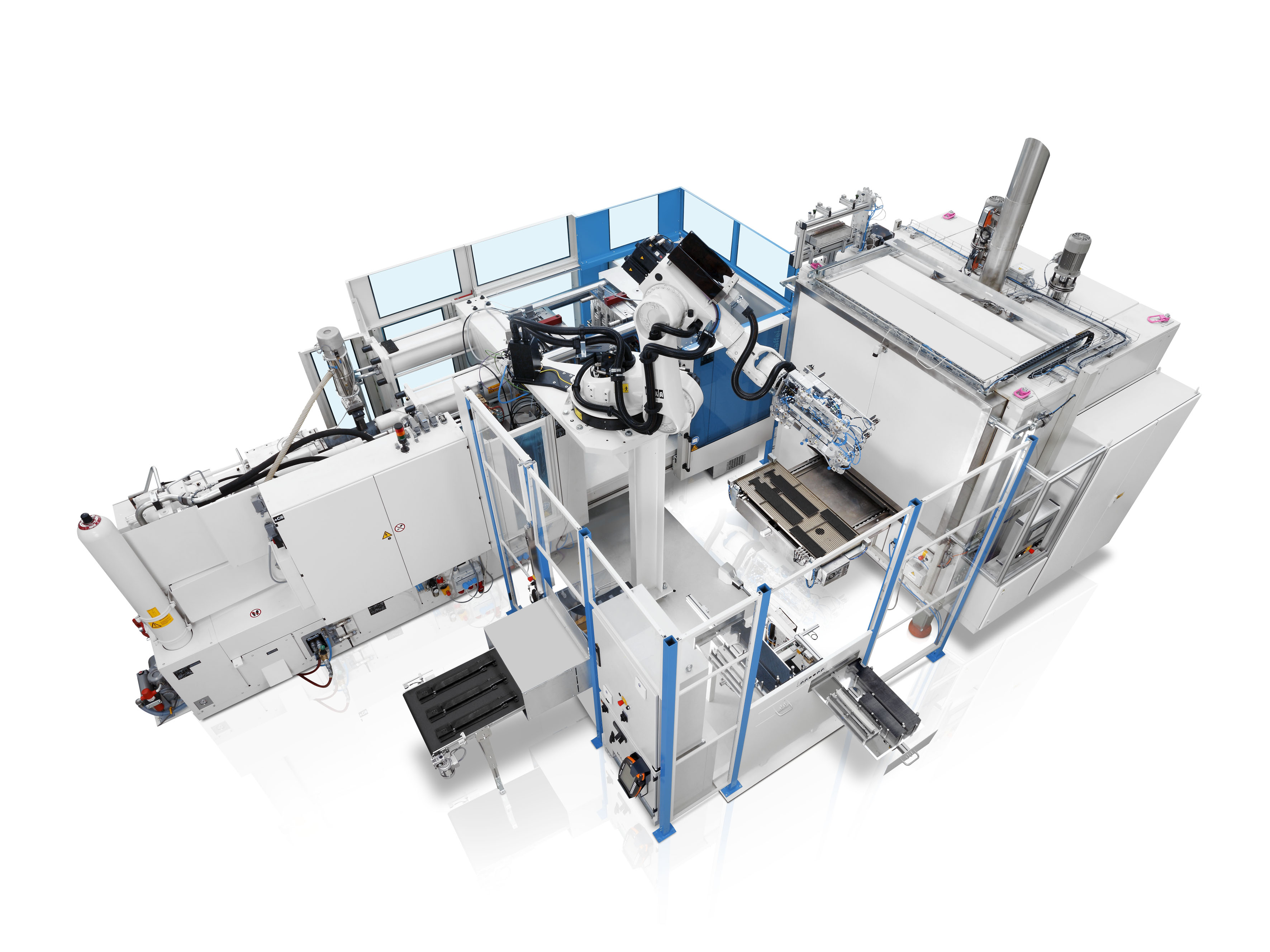

The FiberForm process developed by KraussMaffei combines injection molding with thermoforming of composite sheets to further improve the strength of fiber-reinforced plastics. As a result, the combination of lightweight materials and design in the construction enables new fiber-reinforced thermoplastic components to be manufactured with particularly high strengths. In this process, endless-fiber fabric or textiles impregnated with a thermoplastic matrix are heated, then shaped in the injection mold and finally overmolded. According to Lopez, “This allows ribs to be added for extra stiffness and other functions to be integrated into the process. Since production fits seamlessly in an injection molding operation, the process is ideal for manufacturing lightweight structural components for large-series applications.” Like injection molding, the FiberForm process is easy to automate and can be used in fully automated production with compact manufacturing cells. At the Plastimagen show, a LRX 150 linear robot will handle the composite sheets, supporting fully automatic manufacturing.

KraussMaffei very well positioned in Mexico

KraussMaffei has had a presence in Mexico since 1999 and is the leading machine manufacturer on the market with its extensive range of premium quality products. “In addition to electric and hydraulic injection molding machines, customers in Mexico receive added value through the use of our fast-response service, excellent automation solutions and innovative process technologies. Furthermore,” Lopez explains, “our customers benefit from the possibilities of combining the technologies of injection molding, extrusion and reaction process machinery under one roof. He states further, “Based on our product and service portfolios, which are one-of-a-kind on the market, our leading market position, our expertise and the extraordinarily high dedication of our employees, we will make use of the opportunities for growth in Mexico.”

The KraussMaffei product brand is internationally recognized for its groundbreaking, multitechnology system and process solutions for injection and reaction molding technology and factory automation. With its standalone, modular or standardized machinery and systems, and a wide, customizable service offering, KraussMaffei is a full-system partner for customers in many industry sectors. KraussMaffei bundles many decades of engineering expertise in plastics machinery and is headquartered in Munich, Germany. For more information: www.kraussmaffei.com

The KraussMaffei Group is among the world’s leading suppliers of machinery and systems for producing and processing plastics and rubber. Its products and services cover the whole spectrum of injection and reaction molding and extrusion technology, giving the company a unique position in the industry. The KraussMaffei Group is innovation-powered, supplying its products, processes and services as standard or custom solutions which deliver sustained added value along the customer’s value-adding chain. The company markets it’s offering under the KraussMaffei, KraussMaffei Berstorff and Netstal brands to customers in the automotive, packaging, medical, construction, electrical, electronics and home appliance industries. Continuing a long tradition of engineering excellence, the international KraussMaffei Group currently employs around 4,000 people. With a global network of more than 30 subsidiaries and more than 10 production plants, supported by around 570 sales and service partners, the company is close to customers around the world. KraussMaffei has been headquartered in Munich since 1838. For more information: www.kraussmaffeigroup.com