The renowned German brewery Rothaus inaugurated state-of-the-art sorting and filling lines at their site in the High Black Forest in the beginning of the year. Maximum uptime and increased reliability of these lines were made possible thanks to the line engineering and conveying expertise of their longstanding business partner Gebo Cermex.

Germany, a traditionally strong beer-producing and -drinking country[1], where selecting a beer brand is often a very emotional choice – almost a form of regional patriotism – has numerous regional breweries and microbreweries that produce speciality beers[2]. One of these regionally very popular brews is the Rothaus Pils Tannenzäpfle, produced by Rothaus Brewery, successfully on the market since 1956.

Founded in 1791 by a nearby Benedictine monastery, Rothaus, the most well-known regional brewery in Germany’s Black Forest, has been brewing high-quality beers that have been valued by beer connoisseurs across the country for centuries. Even though overall domestic beer consumption trends in Germany are reflecting the high level of saturation in the market, premium options are projected to grow, with glass remaining by far the leading type of beer packaging in the country[3]. The preference for regional, traditional and high-quality beer will further underpin this development[4], boosting breweries like Rothaus.

High-quality beer calling for continuous investments

Today, the Badische Staatsbrauerei Rothaus AG (Baden State Brewery Rothaus) is recognised as a notable example of success; the reasons for that lie in the premium quality of its beer, the foundation of which are modern brewing facilities. The bottling facility at Rothaus has some of the most advanced technologies available. This is how the brewery can satisfy the high requirements of sanitation and guarantee that customers will always be able to enjoy high-quality beer.

Gebo Cermex, a strong, long-term partner in line engineering

As a case in point in their continuous investment strategy, Rothaus decided to work together with their longstanding partner Gebo Cermex to solve the most recent challenges the brewery was facing. They wanted to replace an ageing bottling line – which in the medium term could no longer guarantee the high hygiene and quality standards of the company. Additionally, they were receiving many returnable glass bottles from other producers that they could not process according to the top productivity control routines they have, as such potentially compromising the high efficiency target of their new filling line. The latter situation was proving particularly harsh in the summer season, when the infeed of bottles typically increases, while the number of operators at the brewery is reduced.

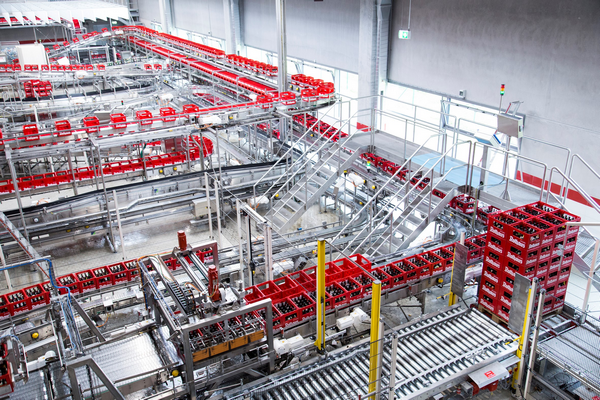

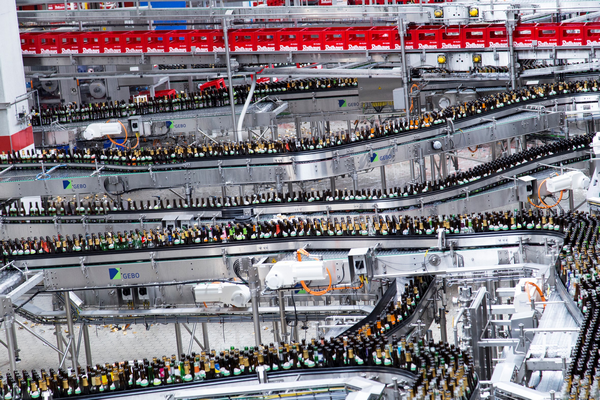

The Gebo Cermex team supplied the integration services for setting up a new sorting and a new bottling line. Working closely with the customer, the company managed to fully integrate 30 different machines from more than a dozen different suppliers, creating a new line that can sort an impressive 3,200 crates per hour and bottle up to 76,800 bph. Additionally, Gebo Cermex provided the crown feeders and the conveying components, including pallets management within the brewery. “Both for the sorting and bottling lines, we successfully answered the request from the customer to limit the number of operators to three per line, thanks to an ‘arena’ layout, giving quick and easy access to all the machines,” says Louis Merienne, Sales Director Europe, Beverage Markets at Gebo Cermex.

Maximum uptime regardless of irregular bottles

Roger Jäger, Director of the filling department at Rothaus, notes, “The big challenge for us was actually the sorting line because this is not a standard line in the classic sense. Here, we are very satisfied: the concepts have very quickly shown that they are perfectly fine. With the new filling line, we can already see utilisation rates of more than 80%. Considering that the line has not yet been running for a full year, this is a remarkable value. This is due to the fact that we are currently supplying only sorted empty containers to the filling line, which of course brings enormous operating safety to the lines.”

The Gebo Cermex solution is able to deliver reliability and efficiency nearly regardless of the percentage of irregular returnable bottles. This means the crates can contain, on average, 40% and in peak times up to 80% of bottles from other producers without causing issues. In addition, the sorting line can run at 85% efficiency in twelve different modes to sort bottles and crates, fill used or new crates – with used or new bottles – and create stocks of empty crates. All of that contributes to a performance increase of the bottling lines, with the one installed most recently working at 90% efficiency.

Louis Merienne further explains the successful partnership between the two companies – established in 1991, “Our globally renowned capabilities in line engineering have been especially appreciated due to the fact that – as an engineering integrator – we are trusted and valued as an independent partner. This relationship of trust has been built through time and on the basis of concrete performances and facts. Thanks to our line engineering expertise, we were able to help Rothaus in setting up the business case and calculating their Return on Investment (ROI) of sorting the goods themselves. Our patented sorting system solution is controlled at the line level: the central automation program regulates the speed of the machines[5], for continuous and seamless running of the whole line, leading to maximum uptime for the customer.”

With their new sorting and filling line, Rothaus remains true to its mission of achieving the best efficiency through smart use of state-of-the-art technology, thus securing a top position in the German brewery landscape.

[1] According to Euromonitor, Germany recorded total volume sales of beer of 9.1 billion litres in 2016.

[2] Euromonitor International June 2017

[3] Euromonitor International June 2017

[4] Euromonitor International June 2017

[5] Including overspeed

About Gebo Cermex

Gebo Cermex works in partnership with Sidel as part of The Sidel Group.

The Sidel Group is formed by the union of two strong brands, Sidel and Gebo Cermex. Together, we are a leading provider of equipment and services for packaging liquid, food, home and personal care products in PET, can, glass and other materials.

With over 37,000 machines installed in more than 190 countries, we have nearly 170 years of proven experience, with a strong focus on advanced systems, line engineering and innovation. Our 5,000+ employees worldwide are passionate about providing complete solutions that fulfil customer needs and boost the performance of their lines, products and businesses.

Delivering this level of performance requires that we continuously understand our customers’ challenges and commit to meeting their unique goals. We do this through dialogue, and by understanding the needs of their markets, production and value chains. We complement this by applying our strong technical knowledge and smart data analytics to support maximum lifetime productivity to its full potential.

We call it Performance through Understanding.