Optimal Utilisation of depleting resources and sustainable production processes are the key drivers of technological innovation these days – and it is here that the Danieli fTSR technology scores a bulls’s eye.

Optimal Utilisation of depleting resources and sustainable production processes are the key drivers of technological innovation these days – and it is here that the Danieli fTSR technology scores a bulls’s eye.

The direct rolling process for hot strip production, where the thin slab caster is connected directly to rolling mill, has gained large market share rapidly because of its remarkable advantages in term of energy savings and investment cost over the conventional hot strip mills. However, the unquestionable advantages of the first-generation applications of such TSCR plant concepts also entail significant limitations both in terms of productivity and steel grades that can be produced. Since its first pioneering applications in this area, Danieli considered strategic development of new technical solutions specifically conceived to overcome these limitations with the goal of increasing plant production volumes and enlarging steel grades in product mix, in order to cover the gap between “Conventional Mill” and “Thin Slab Casting and Rolling” process routes.

Core Sector Communiqué interviewed Mr. Sanat Bhaumik, Sr. Vice President (Flat Products) of DANIELI India to know about the fTSR process and Danieli’s innovations in this technology.

Q1: Why are the steel producers in India presently targeting Thin Slab Casting & Rolling process for hot rolled coil production over conventional Hot Strip mills?

A1 : We all know combining processes will always reduce investment and transformation costs of a plant. So, it is not a surprise that production of hot rolled coils through TSCR route is always going to be cheaper than conventional HSM route. When we produce hot rolled coils directly from liquid steel in a single plant we are able to avoid intermediate storage and reheating of slabs thereby eliminating a few equipment which saves capital cost and ensure no cooling or reheating of slabs saving energy or transformation costs. These CAPEX and OPEX advantages make TSCR technology more preferable over conventional HSM route.

Q2: But can we produce all steel grades in TSCR plants? Again such plants have productivity limitations also.

A2 : Yes, it is true and only for this reason, since its first pioneering pilot plant in 1985, Danieli have always tried to implement solutions which combines the best of both thin slab casting & rolling as well as conventional HSM technologies. Danieli’s fTSR plants overcome the quality and productivity limitations but retain the CAPEX and OPEX advantages of thin slab casting and rolling technology.

Q3: In what way Danieli plants are different from others….

A3 : To describe these differences in a single sentence, I shall say that the differences are mainly in the Caster Design and Configuration of the Hot Strip Mill.

Q4: What are the specialties of the Danieli thin slab caster?

A4 : In the thin slab caster (TSC) area the main special feature is the design of the caster itself. Danieli provides the TSC with Vertical Curved design with its parented Dynamic Soft Reduction (DSR) process. This feature will allow adapting a dedicated roll diagram to cope up with both internal cleanliness and proper ferrostatic pressure during the casing process.

In addition, Danieli patented long funnel H2 mould ensures reduction of the stress on the slab during the solidification phase, which is the key factor to cast crack sensitive grades like real peritectic grades.

Application of Dynamic Soft Reduction (DSR) is a key factor in ensuring optimal internal quality, under all casting conditions, and not only in a limited range of operative conditions.

The Air Mist secondary cooling which allows to fine tune the thermal profile of the slab during solidification in a dynamic way of the casting conditions (such as casting speed, superheat, etc.) with the maximum control range. Danieli thin slab caster also incorporates the unique feature of Independent machine closed circuit cooling for all sensitive elements of the caster (bearings, supports, etc.) to monitor and control the temperature of all maintenance sensitive components of the caster regardless the casting speed and reduces the maintenance issues.

Q5: How these features contribute to the end product which is hot rolled coil?

A5 : Danieli vertical curved TSC have the following major advantages:

- No limitation on metallurgical length (9 – 20 meters).

- Higher casting speeds achievable (up to 8.0mpm). Casting speed is the key point for productivity, safety and quality.

- Allows casting of thicker slabs which is beneficial for quality and productivity

- Casting at lower speed for some crack sensitive grades and also to avoid risk of breakouts (safer operation)

- Lower overall height (< 7.5 meter head)

- Flexible speed of operation (2.5mpm to 8.0mpm) with no limitation of thickness

- Each segment can be removed individually without disturbing other segments in the line

- Dynamic Soft Reduction reduces centre line segregation and helps in refining grain size.

Q6: You have also mentioned about hot strip mill configuration of Danieli. How it is different from other TSCR plants?

A6 : Starting from its first applications of TSR (Thin Slab Rolling) plants, where all rolling stands are arranged in a single Finishing Mill train operating in tandem, Danieli implemented several mill stands arrangements with separation between Roughing Stands and Finishing stands, in order to apply advanced rolling practices, such as ferritic rolling and thermo mechanical rolling, typically adopted in conventional Hot Strip Mills. These are fTSR (flexible Thin Slab Rolling), QSP (Quality Strip Production) and ETR (Extra Thin Rolling) plant configurations.

Q7: Where are such plants installed?

A7 : The only TSR plant is installed in Esfahan Steel (Iran) and the ETR in POSCO (Korea). Danieli has a number fTSR installations in Dong Bu (Korea), Tong Hua, Benxi & Bao Steel (China), MMK Atakas (Turkey), Severstal Lucchini (Italy) and NMDC (the first fTSR plant in India under implementation). The QSP installations are in Essar Algoma (Canada), North Star BHP (USA), Ezz Steel (Egypt) and OMK (Russia).

Q8: How will such HSM configurations benefit the plant?

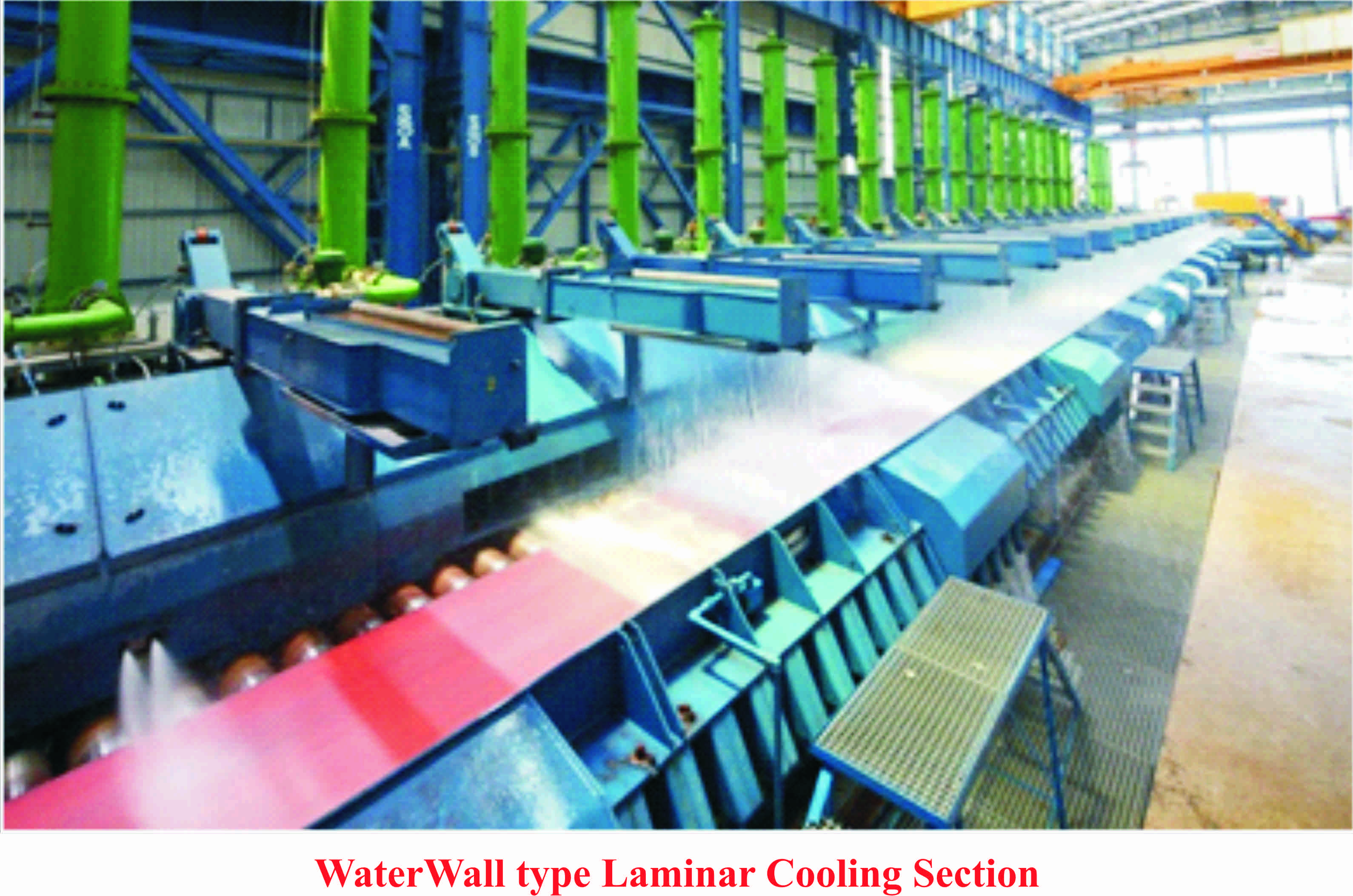

A8 : Separation between the RM and FM trains allows installation of some strategic equipment like intermediate cooling, crop shear and an onboard descaler before the finishing mill. The intermediate cooling section will allow thermo-mechanical rolling or finish rolling of transfer bar with lower temperature. The crop shear can be used to cut the head end of the transfer bar for smooth threading through the finishing mill which reduces the cobble rate particularly during production of thinner gauges. Furthermore, the distance between R2 and F1 ensures higher strip internal quality because adequate re-crystallization time is available between R2 and F1 passes. This is a must for rolling API grades.

Q9: Tell us about some land marks achieved by Danieli thin slab casting and rolling plants.

A9 : There are many such land marks, out of which I would like to specially mention about some plants. Essar Algoma DSPC, Canada was the first plant in the world to cast real peritectic grades since 1997 in a thin slab casting facility. Tangshan Iron and Steel, China is the first plant in the world overcoming the 3.0Mtpy productivity in 2005 (with 2 strands in operation). Benxi Iron and Steel in China pioneered the production of high Silicon grades since 2008. Posco CEM Plant in Korea is the first ultra high speed thin slab caster (>7.5mpm) in operation since 2009.

Q10: Do you think TSCR plants will be able produce replace conventional HSM to produce all grades and quality of hot rolled coils?

A10 : My reply to this question will be a big “Yes”. In fact all research activities in Danieli for TSCR technology are targeted to achieve this goal. Lot of progress has been made over the years after the first TSR plant installed at Esfahan Steel, Iran in 1989 with production capacity of only 0.8mtpy for single strand casting line. Today the ETR in POSCO, CEM plant can produce 2.0mtpy for a single strand casting line.

Similarly, TSR in 1989 produced only commercial quality hot rolled coils and gradually more grades were produced in DANIELI’s subsequent plants – peritectic in 1997, HSLA in 2000, API grades in 2005, Silicon steel (up to 3.2% Si) in 2009, Arctic API in 2010 and AHSS in 2011. Continuous efforts by a dedicated technology team are underway to reach the ultimate target mentioned by you but it will take time.