MMPZ, Belarus, visits SMS group’s test field in Mönchengladbach for the Plug & Work integration tests of the new tinplate production facility

SMS group (www.sms-group.com) has demonstrated MMPZ-group (Miorskij Metalloprokatnyi Zavod) the set-up and performance of a Plug & Work integration test at its new test center in Mönchengladbach. The tests involved the simulation of the customer’s new reversing cold mill (RCM) to be installed in Belarus. The automation system of the RCM, which is going be commissioned already in 2018, was now thoroughly tested in Mönchengladbach in a very realistic simulation environment. In the test center, crucial parts of the automation system were arranged in a functional set-up, using the genuine control cabinets, computers, control pulpits and software of the future plant. Delegates of MMPZ observed the testing procedures of the proven Plug & Work concept, which will later on save time during the commissioning and ramp-up of the plant. SMS group uses hybrid real-time simulation techniques to simulate the specific mechanical, drive and process technology of its customers’ production plants in a near-reality environment. Thus SMS group can test and optimize the automation systems in the test center under very realistic conditions before the equipment is shipped to its customers and commissioned on site. Plug & Work now also integrates 3D simulation to train the future operating staff on the genuine control pulpits. In 3D, complex functions and sequences can be visualized even more realistically and clearly.

The new test center in Mönchengladbach covers an area of 800 square meters, enough space to set up equipment for several integration tests at a time and performing various tests in parallel.

Dr. Vladimir Tishenko, First Vice General Director of MMPZ, was deeply impressed by the tests. He who has dedicated his entire career to metallurgy comments: “It is a fascinating experience to see at this early stage how our new reversing cold mill, its functions and features will be working in the future. This state-of-the-art mill will set new standards in Belarus.”

As part of the Plug & Work concept, SMS group integrates a professional interactive 3D graphical application into the simulation environment to enhance the visualization of the production processes. Peter Waldhoff, Project Director, E&A Flat Rolling Mills at SMS group, says: “By visualizing the plants in 3D, we can show our customers the mechanical components and movements even more realistically. This is particularly beneficial in situations where the future operators have not seen the new equipment before. Also the individual process steps within a plant can be much more realistically visualized in 3D“

Large-scale order from Belarus

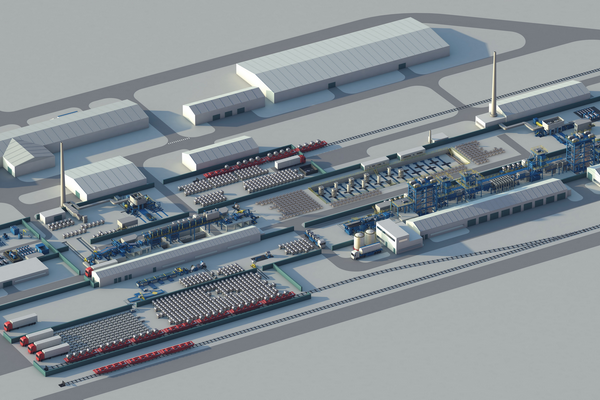

MMPZ-group has chosen SMS group as supplier for a new tinplate production complex in Miory, Belarus. SMS group is going to supply the complete rolling and strip processing plants, including the X-Pact® electrical and automation equipment. The supply scope comprises a reversing cold mill, an electrolytic cleaning line, a batch annealing facility, a two-stand DCR (Double Cold Reduction) mill, an electrolytic tinning line and two packaging lines, one for sheet packs and one for coiled product.

Initially, plants for an annual capacity of 150,000 tons of product in tinplate grades T1, T2, T3, DR7 and DR8 as well as sheet in CQ und DQ grades will be installed. Provision will be made for a future capacity increase to up to 240,000 tons. The first facilities are scheduled to become operational in early September 2018. MMPZ plans to use the new facilities mainly to produce tinplate for the packaging industry and cold-rolled sheet. Most of the mill output is intended to be exported, mainly to Russia and other CIS markets, but also to EU countries.

The reversing cold mill of MMPZ-group

The Plug & Work-tested reversing cold mill will be equipped with one pay-off reel and two reversing reels. The six-high mill stand with CVC®plus technology will be able to produce sheet in CQ and DQ grades as well as tinplate down to a minimal final gage of 0.15 millimeters for subsequent coating in the electrolytic tinning line. The mill will feature the new high-performance design of cold rolling mills built by SMS group. It will use very slim work rolls, which make mill operation highly efficient, as they allow high reductions per pass to be achieved with comparatively low rolling forces. In addition to the CVC®plus technology, features such as work roll and intermediate roll bending, multi-zone cooling and the DS system will guarantee that the strip has the quality the customer demands in terms of strip thickness, flatness and surface quality.