– Extended by two clamp sizes for Chinaplas

– Production in Haiyan (China) in line with global quality standards of the KraussMaffei Group

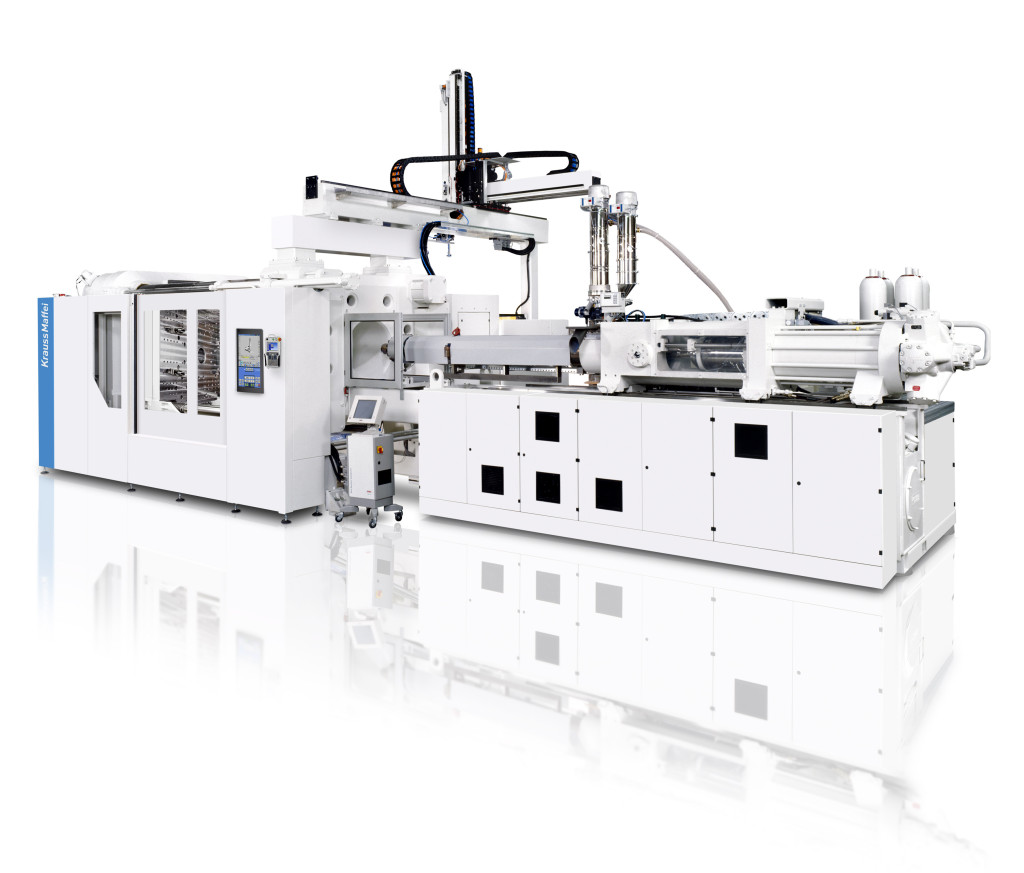

Powerful. Versatile. Durable.

KraussMaffei has been producing the MX series at Haiyan, specially tailored for the needs of Chinese customers, since 2012. “Since then, the MX series hat successfully become established on the market. Demand is increasing this year,” explains Christian Blatt, CEO of the KraussMaffei Group in China. This success is based on a combination of the high quality standards of the KraussMaffei Group, which are appreciated all round the world, and the fast and cost-effective production for the local customers. “Optimized production processes have enabled throughput times to be shortened by almost half, which is extremely welcome news for our customers,” Blatt continues. Added to this are the additional time advantages since, among other things, there is no need to transport items from Europe, along with a faster availability of spare parts and a service package that is tailored to meet local needs.

At the Chinaplas, KraussMaffei will be expanding the MX series for China upward with two new clamp sizes. “We are receiving ever more inquiries requesting higher clamping forces, especially from the automotive industry. With the new MX 2700 and MX 3200, we are able to offer our local customers efficient and flexible production solutions with clamping forces of 27,000 kN and 32,000 kN respectively,” explains Jörg Wittgrebe, Sales Director China at KraussMaffei.

Achieve a competitive edge, flexibly

Plastics processors are increasingly having to address the issues of higher productivity and rising labor costs, even in China and South-East Asia. This means that flexible machine concepts are becoming ever more important. “The great adaptability of the MX series for different applications is ideal here, and is being employed by ever more customers. “2015 got off to a promising start, which means that we will continue to participate in growing markets and further expand our presence in Asia,” says Blatt. The MC series is predestined above all for applications in the automotive, packaging and logistics industries.

Characteristic of the MX series is the hydromechanical two-platen clamping unit developed by KraussMaffei. This represents robust construction, fast production and low-maintenance operation. Force flow-optimized sliding shoes in combination with guided tiebars guarantee exactly parallel clamping movements and permanent mold protection. Other advantages of the MX series are the superb melt quality and the excellent shot weight consistency. All in all, the MX series offers consistently high quality with good productivity, even in tough continuous operations.

The KraussMaffei product brand is internationally recognized for its groundbreaking, multitechnology system and process solutions for injection and reaction molding technology and factory automation. With its standalone, modular or standardized machinery and systems, and a wide, customizable service offering, KraussMaffei is a full-system partner for customers in many industry sectors. KraussMaffei bundles many decades of engineering expertise in plastics machinery and is headquartered in Munich, Germany. For more information: www.kraussmaffei.com

The KraussMaffei Group is among the world’s leading suppliers of machinery and systems for producing and processing plastics and rubber. Its products and services cover the whole spectrum of injection and reaction molding and extrusion technology, giving the company a unique position in the industry. The KraussMaffei Group is innovation-powered, supplying its products, processes and services as standard or custom solutions which deliver sustained added value along the customer’s value-adding chain. The company markets it’s offering under the KraussMaffei, KraussMaffei Berstorff and Netstal brands to customers in the automotive, packaging, medical, construction, electrical, electronics and home appliance industries. Continuing a long tradition of engineering excellence, the international KraussMaffei Group currently employs around 4,000 people. With a global network of more than 30 subsidiaries and more than 10 production plants, supported by around 570 sales and service partners, the company is close to customers around the world. KraussMaffei has been headquartered in Munich since 1838. For more information: www.kraussmaffeigroup.com