Changzhou ChangBao from Changzhou, Jiangsu Province, China, has placed an order with SMS Meer, Germany, for the supply of a new stretch-reducing mill, including automation system. The scope of supply also includes a CARTA® technology package and a KR III 25 CNC groove dressing machine.

Changzhou ChangBao from Changzhou, Jiangsu Province, China, has placed an order with SMS Meer, Germany, for the supply of a new stretch-reducing mill, including automation system. The scope of supply also includes a CARTA® technology package and a KR III 25 CNC groove dressing machine.

The stretch-reducing mill for Changzhou ChangBao will have the SMS Meer single universal drive. This means that each roll shaft is driven individually by an electric motor. Furthermore, SMS Meer is taking over the project management, supervision of erection and commissioning and the training of the operating personnel.

The stretch-reducing mill will be used to produce seamless tubes in the diameter range from 26.7 to 114.3 mm.

The mill has an annual capacity of around 100,000 t allowing the production of heavy-walled tubes with small diameters from high-alloy steels. In comparison with conventional stretch-reducing mills, the undesirable internal polygonization does not occur here. An internal polygon is a wall thickness irregularity of hexagonal shape that occurs in particular in tubes with large wall thicknesses and small diameters.

As with all wall thickness irregularities, internal polygonization also leads to an impairment of product quality.

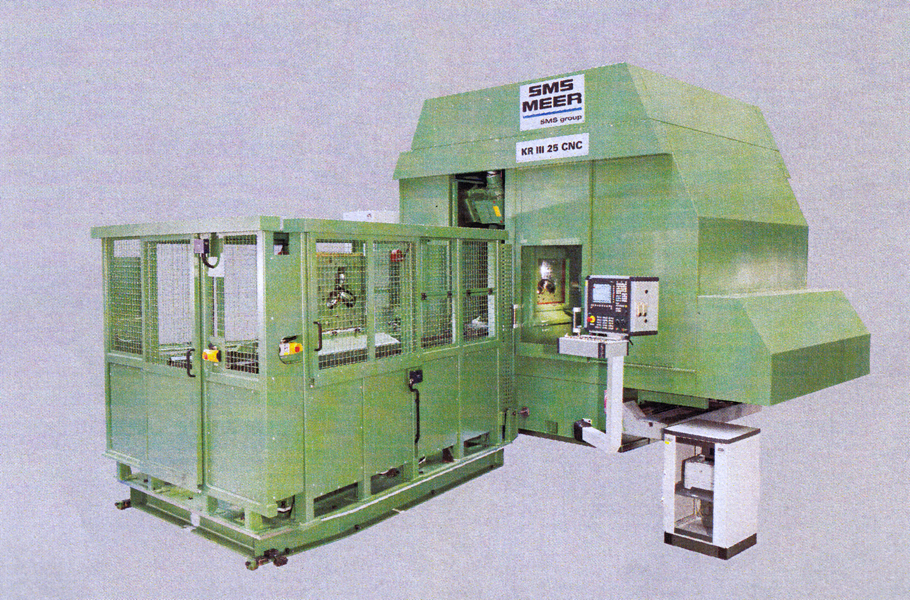

Groove dressing machine with free groove design

Changzhou ChangBao has also ordered a KR III 25 CNC groove dressing machine from SMS Meer for machining the rolls of the new stretch-reducing mill. The grooves in the rolls can be machined fully automatically on this machine. The diameter of the rolls to be dressed is 250 mm.

The machine is equipped with a measuring device which automatically records the stand and roll data under program control. The machining of the rolls individually in turn from the front side of the stand allows any desired groove form to be produced and the edge radii to be machined in a single pass.

The ceramic cutters in the mount system allow optimum cutting conditions and short changing times. The grooves are automatically machined in two passes – with high precision and independently of the operator – over a total period of less than 30 minutes.

Changes to the groove forms are easily possible by quick reprogramming of the machine. Interfacing with works databases and control systems, such as the CARTA® (Computer Aided Rolling Technology Application) technology system from SMS Meer, is also assured.

The stretch-reducing mill and groove dressing machine will go into production in January 2013.