Saarstahl AG, Völklingen, has ordered a five-strand billet caster for their steelplant in Völklingen, Germany, from SMS Concast. The new casting plant is going to be designed for an annual capacity of 850,000 tons of billets. Start of operation is planned for the third quarter of 2019.

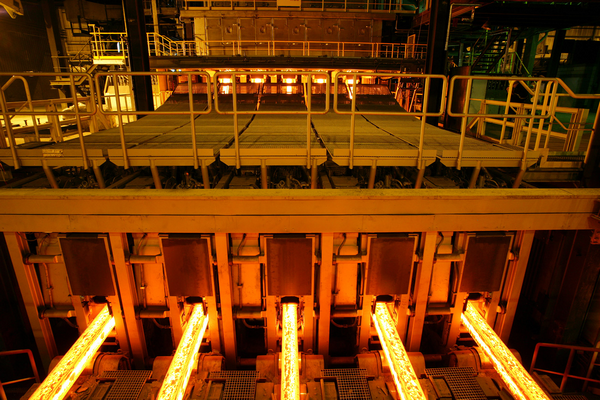

The new casting machine, to be named S1, will produce 180 x 180 millimeter square billets in a wide range of steel grades, including bearing steels, spring steels, cold heading wire rod and free-cutting steels. Products made of these steel grades are used in the automotive industry and in mechanical engineering applications.

The S1 continuous casting machine will come with state-of-the-art equipment such as Convex molds, hydraulic mold oscillator, electromagnetic mold and strand stirrers, mechanical soft reduction and modern automation and communication technology according to Industry 4.0 standards.

Saarstahl was the first steel producer worldwide to apply mechanical soft reduction in billet casting. The investment in a new caster is further strengthening the company’s leadership position in mechanical soft reduction technology.

Saarstahl is one of the world‘s leading manufacturers of high-quality steel grades. It has a longstanding business relationship with SMS Concast, going back to the year 2002 when SMS Concast supplied a first continuous caster to Saarstahl, followed by the supply of a second one in 2007.